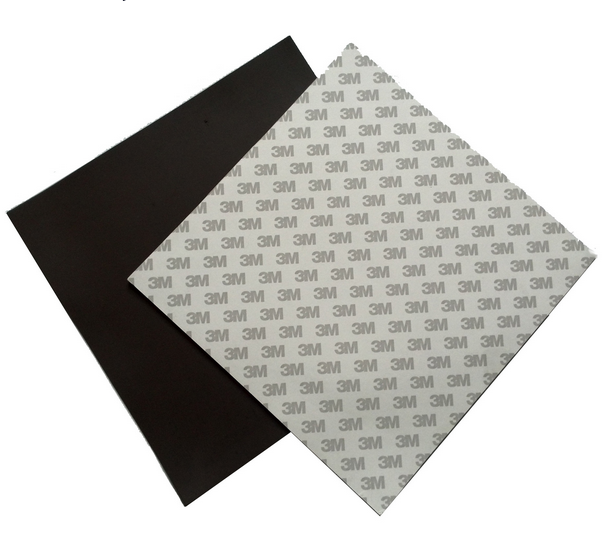

RFID electronic magnetic cloth 300*300*2mm ferrite wave absorbing material card reader metal circuit board mask

Name: RFID ferrite magnetic cloth 300*300*1m

m NFC anti-metal

romagnetic interference wave absorbing material Model: RFCL100 Absorbent material, also known as magnetic masking material, metal isolation material, anti-metal material, ferrite material, commonly known as "magnetic cloth".

Flexible soft magnetic glue + resin + rare metal polymer is mixed in a certain proportion to form a flexible impact-resistant sheet soft magnetic material. Since it can easily match impedance in high frequency bands, it can achieve a high magnetic convergence effect, has excellent absorption and anti-projection performance, and has a wide range of applications and a rich product group in the field

of communication technology. In recent years, it has played a significant role in isolating interference in the rapid development of RFID Internet of Things systems and NFC short-distance

electronic payment systems and in an integrated installation environment made of metal materials. The wave absorbing materia

l canabsorb most electromagnetic waves, reduce the interference of electromagnetic waves to components, reduce and suppress th

e electromagnetic coupling between electronic components, realize the integration of IC card\tag and metal. It is especially suitable for induction frequencies of 125KHz and 13.56MHz, so that ID cards and RFID electronic tag cards can be used normally in an environment of metal and electromagnetic interference, and play the role of isolating and absorbing electromagnetic wave interference. The current standard sizes of wave absorbing materials are 300mm×300mm, 200*200mm, etc. (You can use glue backing according to customer needs, and you can open the mold and cut it into other appearance shapes and size thicknesses, such as small rectangles or rounds, punch holes, etc.). The thicknesses are: 0.3mm, 0.5mm, 1.0mm, 2.0mm, of which 0.3mm and 0.5mm are mostly used for RFID electronic tag packaging to resist metal tag use. 1.0mm and 2.0mm are mostly suitable for embedded inside or pasting outside of RFID reader and writer equipment to prevent interference caused by the antenna and internal circuit board of the reader or writer and metal products (such as the reader and writer hanging on stainless steel doors), and can greatly improve the performance of the reader and write identification tag card. This material can be packaged with a variety of low-frequency and high-frequency RFID chip tags and other shell materials to form anti-metal tags, such as TK4100, EM4001, TI Tag, Philips, Fudan FM08 and other wafers, with frequencies of 125KHz and 13.56MHz. The agreed standard can support ISO15693, ISO14443A/B, etc. The anti-metal tag product is attached to the paste or the screw turns are fixed to the surface of the metal product. The identification and induction reading and writing distance is generally around 1-10cm. Material characteristics: 1. Soft and not easy to brittle; 2. Rich in rare metal elements such as (Mg, Mn, Ni, Cu, etc.); 3. Thin, flexible, flexible, flexible, and good physical properties; 4. Diversified sizes and shapes (the size can be adjusted according to customer requirements); 5. It has adhesive backing, which is convenient and easy to use; 6. Comply with environmental protection standards. Application features: 1. Applied to RFID to improve readability and sensitivity; 2. Absorb electromagnetic waves and reduce interference to components; 3. It can realize the integration of IC tags/cards and metals; 4. Reduce and suppress electromagnetic coupling between electronic components; 5. It has isolation performance and improves the product's anti-electronic interference ability.| Product Name | RFID electronic magnetic cloth 300*300*2mm ferrite wave absorbing material card reader metal circuit board mask |

|---|---|

| SKU | RFID_other-TW |

| Weight | 1.000000 |

| Customizable | No |

| With Built-in Battery | No |

| Warranty | 1 Year Warranty |

| Country Specific | Universal |

| selling_potential | 3 |

| Minimum Order Quantity | Yes |

| Description | Name: RFID ferrite magnetic cloth 300*300*1m romagnetic interference wave absorbing material Model: RFCL100 Absorbent material, also known as magnetic masking material, metal isolation material, anti-metal material, ferrite material, commonly known as "magnetic cloth". Flexible soft magnetic glue + resin + rare metal polymer is mixed in a certain proportion to form a flexible impact-resistant sheet soft magnetic material. Since it can easily match impedance in high frequency bands, it can achieve a high magnetic convergence effect, has excellent absorption and anti-projection performance, and has a wide range of applications and a rich product group in the field of communication technology. In recent years, it has played a significant role in isolating interference in the rapid development of RFID Internet of Things systems and NFC short-distance electronic payment systems and in an integrated installation environment made of metal materials. The wave absorbing materia l canabsorb most electromagnetic waves, reduce the interference of electromagnetic waves to components, reduce and suppress th e electromagnetic coupling between electronic components, realize the integration of IC card\tag and metal. It is especially suitable for induction frequencies of 125KHz and 13.56MHz, so that ID cards and RFID electronic tag cards can be used normally in an environment of metal and electromagnetic interference, and play the role of isolating and absorbing electromagnetic wave interference. The current standard sizes of wave absorbing materials are 300mm×300mm, 200*200mm, etc. (You can use glue backing according to customer needs, and you can open the mold and cut it into other appearance shapes and size thicknesses, such as small rectangles or rounds, punch holes, etc.). The thicknesses are: 0.3mm, 0.5mm, 1.0mm, 2.0mm, of which 0.3mm and 0.5mm are mostly used for RFID electronic tag packaging to resist metal tag use. 1.0mm and 2.0mm are mostly suitable for embedded inside or pasting outside of RFID reader and writer equipment to prevent interference caused by the antenna and internal circuit board of the reader or writer and metal products (such as the reader and writer hanging on stainless steel doors), and can greatly improve the performance of the reader and write identification tag card. This material can be packaged with a variety of low-frequency and high-frequency RFID chip tags and other shell materials to form anti-metal tags, such as TK4100, EM4001, TI Tag, Philips, Fudan FM08 and other wafers, with frequencies of 125KHz and 13.56MHz. The agreed standard can support ISO15693, ISO14443A/B, etc. The anti-metal tag product is attached to the paste or the screw turns are fixed to the surface of the metal product. The identification and induction reading and writing distance is generally around 1-10cm. Material characteristics: 1. Soft and not easy to brittle; 2. Rich in rare metal elements such as (Mg, Mn, Ni, Cu, etc.); 3. Thin, flexible, flexible, flexible, and good physical properties; 4. Diversified sizes and shapes (the size can be adjusted according to customer requirements); 5. It has adhesive backing, which is convenient and easy to use; 6. Comply with environmental protection standards. Application features: 1. Applied to RFID to improve readability and sensitivity; 2. Absorb electromagnetic waves and reduce interference to components; 3. It can realize the integration of IC tags/cards and metals; 4. Reduce and suppress electromagnetic coupling between electronic components; 5. It has isolation performance and improves the product's anti-electronic interference ability. |

| Condition | New |

Still have a question? No worries.